Smooth Coating of PTCA Wire

-

2021-07-14

-

LEPU

1. PTCA wire needs coating treatment

The purpose of the PTCA wire coating is to reduce the friction of the guide wire, improve tracking, and facilitate the delivery of equipment. The coating material must have stable chemical properties, good biocompatibility, and anti-thrombotic effect. According to its characteristics, it can be divided into two types: hydrophilic and hydrophobic.

The most commonly used hydrophobic coatings are polytetrafluoroethylene, dihydrofluorescein and silicone resin; hydrophilic coatings include Hydro-track, Hydro-coat and M-Coat VR polymers.

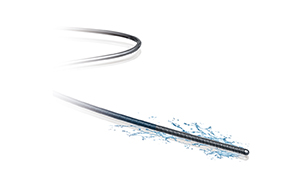

The hydrophilic coating is a thin layer of matte substance in the dry state, which absorbs water molecules to form a smooth gel-like surface and reduce the friction of the PTCA wire.

The hydrophobic coating repels water molecules and makes the surface smooth and waxy, which also reduces the friction on the surface of the guide wire and improves the tracking.

2. PTCA wire hydrophilic coating and hydrophilic guide wire

It should be noted that there are conceptual differences between hydrophilic coatings and hydrophilic guide wires (also called super-smooth guide wires). Not all PTCA wires with hydrophilic coatings can be called hydrophilic guide wires.

The common feature of the hydrophilic guide wire is a smooth polymer sheath. The polymer sheath covers the head end of the guide wire or the entire guide wire. The outer surface of the sheath is coated with hydrophilic coating, so that the smoothness of the PTCA wire is further improved, which makes it easy to find the microchannel in the occluded lesion and pass through the micropore with less resistance, thereby increasing the success rate of intervention of CTO lesions. This feature makes hydrophilic guide wires often used in combination with non-hydrophilic rigid guide wires. In addition, the polymer sheath and smooth coating also make it difficult to maintain the shape of the guide wire head end, which increases the complexity of the operation.